KFAS: Fanuc CNC Parts & Repair

Fanuc Series 0i Model D

Fanuc Series 0i-TD

Fanuc Series 0i-MD

Fanuc Series 0i Mate-TD

Fanuc Series 0i Mate-MD

Related manuals

DESCRIPTIONS: B-64302EN

CONNECTION (HARDWARE): B-64303EN

CONNECTION (FUNCTION): B-64303EN-1

USERíS MANUAL (Lathe/Mill): B-64304EN

USERíS MANUAL (Lathe): B-64304EN-1

USERíS MANUAL (Mill): B-64304EN-2

MAINTENANCE: B-64305EN

PARAMETER: B-64310EN

Hardware

Main boards

A0

A20B-8200-0540

A20B-8200-0844

A20B-8201-0084

A1

A20B-8200-0541

A20B-8200-0845

A20B-8200-0925

A20B-8201-0085

A2

A20B-8200-0542

A20B-8200-0846

A20B-8201-0086

A3

A20B-8200-0543

A20B-8200-0847

A20B-8200-0927

A20B-8201-0087

A5 0i-Mate

A20B-8200-0545

A20B-8200-0849

A20B-8201-0089

A0U

with USB

A20B-8200-0840

A20B-8200-0080

A0UH with USB High Speed

A20B-8201-0310

A1U

with USB

A20B-8200-0841

A20B-8200-0921

A20B-8200-0081

A1UH with USB High Speed

A20B-8201-0311

A2U

with USB

A20B-8200-0842

A20B-8200-0082

A2UH with USB High Speed

A20B-8201-0312

A3U

with USB

A20B-8200-0843

A20B-8200-0923

A20B-8200-0083

A3UH with USB High Speed

A20B-8201-0313

A5U 0i-Mate

A20B-8200-0548

A20B-8200-0088

Axis Cards

A20B-3300-0635: 2 axes

A20B-3300-0638: 4 axes

A20B-3300-0637: 5

axes

A20B-3300-0632: 6 axes

A20B-3300-0631: 8 axes

Power Supply

A20B-8200-0560

A20B-8200-0570: 2 slots

FROM/ SRAM Module

A20B-3900-0280: FROM

128MB, SRAM 1MB

A20B-3900-0281: FROM 128MB, SRAM

2MB

A20B-3900-0286: FROM 64MB, SRAM 1MB

A20B-3900-0242: FROM 64MB, SRAM 1MB

A20B-3900-0240: FROM 128MB, SRAM 1MB

A20B-3900-0241: FROM 128MB, SRAM 2MB

Fast Ethernet

board

A20B-8101-0030

PROFIBUS-DP master board

A20B-8101-0050

PROFIBUS-DP slave board

A20B-8101-0100

FL-net board

A20B-8101-0031

DeviceNet master board

A20B-8101-0220

DeviceNet slave board

A20B-8101-0330

Inverter (for 8.4" color LCD)

A20B-8002-0703

Inverter (for 10.4" color LCD)

A20B-8002-0702

Touch panel control printed circuit board

A20B-8002-0312

Cooling Fans

A90L-0001-0551#A

A90L-0001-0552#A

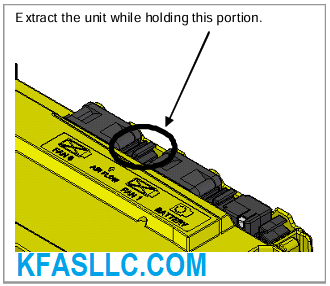

Cooling Fan Replacement Procedure

<1> Before replacing a fan unit, turn off the power to the CNC.

<2> Remove the fan unit to be replaced by holding the latch of the fan unit, and

pull the fan upward.

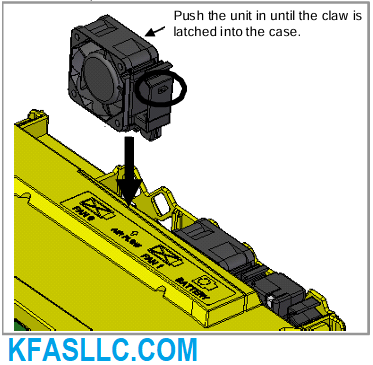

<3> Mount a new fan unit. (Push the fan unit in until the claw is latched into the case.)

REPLACING BATTERY

Offset data, and system parameters are stored in SRAM in the control unit.

The power to the SRAM is backed up by a lithium battery mounted on the control unit.

This battery can maintain the contents of memory for about a year.

When the voltage of the battery becomes low, alarm message "BAT" blinks on the display.

When this alarm is displayed, replace the battery as soon as possible.

If the voltage of the battery becomes any lower, memory can no longer be backed up.

Turning off the power to the control unit in battery low state causes system alarm to occur because the contents of memory is corrupted.

Clear the entire memory and reenter data after replacing the battery.

Therefore it is recommended that the battery be replaced periodically, once a year, regardless of whether a battery alarm is issued.

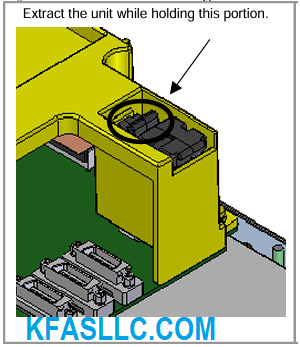

Lithium Battery Replacement Procedure

Prepare a new battery unit (ordering code: A98L-0031-0028).

(1) Turn on the power to the CNC. After about 30 seconds, turn off the power.

(2) Extract the old battery unit from the lower right of the rear of the CNC unit.

(Hold the latch of the battery unit, and extract the unit upward while releasing the claw from the case.)

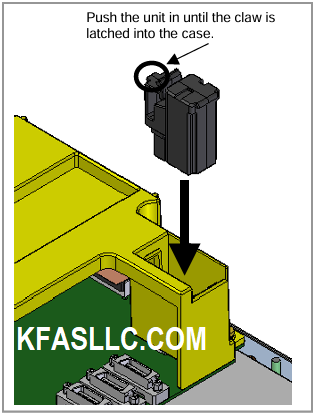

(3) Mount the new battery unit. (Push the battery unit in until the claw is latched into the case.)

Ensure that the latch is engaged securely.

© Copyright

KFASLLC Houston, Texas, USA

© Copyright

KFASLLC Houston, Texas, USA